Advancements in technology have always impacted the automotive industry, but automation is taking efficiency to a whole new level. What once relied heavily on manual labor is now being streamlined through robotics, artificial intelligence, and smart software. Every stage of the automotive process, from manufacturing and inventory tracking to customer service and logistics, has seen noteworthy improvements with automation.

Companies that integrate automated systems are reducing costs, speeding up production, and improving overall accuracy. Automation is not just about replacing human effort; it is about creating smoother workflows, improving quality, and making businesses more adaptable. With supply chains becoming more complex, customer demands increasing, and technology advancing, automation is shaping the future of the automotive industry like never before.

Let’s discuss this further below:

Optimizing Inventory with Smart Software Solutions

Efficiently managing automotive parts is one of the biggest challenges in the industry. Whether it is a manufacturer, dealership, or repair shop, every business relies on keeping the right parts stocked without overloading storage or running into shortages. Manual inventory tracking can result in mistakes, delays, and unnecessary expenses. Without an efficient system, businesses struggle to keep up with demand and maintain seamless operations.

Many companies are now switching to parts inventory management software to handle stock levels automatically. This technology allows businesses to track, organize, and replenish inventory in real-time, reducing errors and preventing unexpected stock shortages. Automated systems can predict future demand, adjust supply orders, and integrate with logistics platforms to create a more efficient flow of materials. Instead of wasting time manually counting parts or dealing with supply chain disruptions, businesses can focus on customer service, production improvements, and long-term growth.

Transforming Manufacturing with Robotic Automation

The rise of robotics in automotive manufacturing has completely changed the way vehicles are built. Factories once depended entirely on manual labor, but now robotic arms, AI-powered assembly lines, and automated quality control systems are making production faster, safer, and more precise.

Robotic automation allows manufacturers to handle repetitive and physically demanding tasks with greater efficiency. Machines can work around the clock without fatigue, increasing production output while reducing labor costs. With robots assisting in welding, painting, and component assembly, workers can focus on technical roles, quality assurance, and system maintenance.

Enhancing Quality Control and Precision Engineering

Producing high-quality vehicles requires extreme precision, and automation plays a crucial role in achieving consistent standards. Traditional quality control relied heavily on manual inspections, which were time-consuming and prone to human error. While skilled workers are essential in identifying defects, automated inspection systems can analyze thousands of parts per minute with unmatched accuracy.

AI-powered cameras, laser sensors, and real-time analytics identify even the smallest inconsistencies in materials, assembly, and final production. When issues are detected early, manufacturers can prevent costly recalls, reduce material waste, and maintain high-quality standards. Apart from speeding up inspections, automation improves the overall reliability and safety of vehicles before they reach consumers.

Streamlining Logistics and Supply Chain Management

The efficiency of the automotive industry relies on well-organized supply chains and smooth logistics operations. A single delay in sourcing parts can slow down production, increase costs, and frustrate customers. Many businesses face challenges in tracking shipments, managing warehouse storage, and predicting supply needs in real-time.

Automated logistics solutions use AI, GPS tracking, and predictive analytics to create a more efficient supply chain. Companies can track shipments, optimize delivery routes, and adjust schedules based on real-time demand. Smart warehouse systems also help businesses reduce storage costs and eliminate waste, ensuring that production never halts due to missing parts. This level of automation allows companies to improve efficiency, minimize disruptions, and meet deadlines with greater accuracy.

Improving Customer Service with AI and Chatbots

Automation is not just changing the way cars are made. It also improves how customers interact with automotive businesses. Dealerships, service centers, and manufacturers are using AI-powered chatbots and virtual assistants to make customer service faster and more efficient. These systems handle inquiries, book service appointments, and provide answers to common questions without requiring human representatives.

Unlike traditional customer service, AI chatbots operate 24/7, allowing customers to get assistance at any time. Whether it is checking vehicle availability, scheduling a test drive, or getting maintenance reminders, automated systems simplify the process. In turn, this reduces wait times, frees up employees for more personalized interactions, and makes the entire customer experience smoother and more convenient.

Increasing Safety Through Autonomous Testing and AI

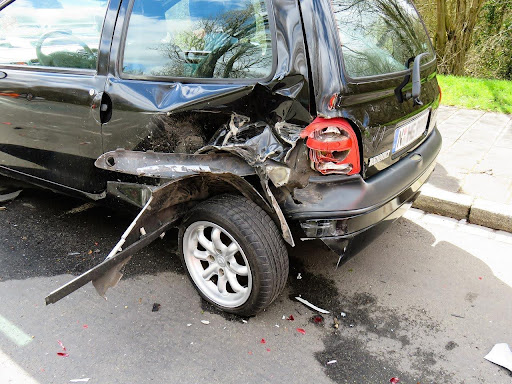

Automation is also playing a major role in vehicle safety and testing procedures. Before a new model reaches the market, it must go through extensive safety evaluations to meet strict industry standards. Traditional crash tests and road trials are still important, but AI-powered simulations and automation-driven testing environments allow for even more precise safety assessments.

Manufacturers use autonomous driving simulations to test different road conditions, weather scenarios, and emergencies. AI systems analyze data from these tests, making it easier to refine safety features before production. Automated testing speeds up the development process, helps engineers identify weaknesses faster, and ultimately results in safer vehicles for consumers.

Smart Energy Management

Automation is also helping automotive companies cut operational costs and reduce waste. Smart energy management systems track factory power usage, optimize equipment performance, and reduce unnecessary energy consumption.

Automated energy systems help manufacturers monitor machine efficiency, control heating and cooling in factories, and manage electricity consumption more effectively. Businesses that implement these solutions can lower costs, extend equipment lifespan, and meet environmental regulations without sacrificing productivity.

Preparing for the Future of Fully Automated Vehicles

As automation continues to advance, the industry is moving closer to fully autonomous vehicles. Self-driving technology, AI-powered navigation, and advanced sensors are shaping the future of transportation. Automotive companies are investing in automation to improve traffic flow, increase vehicle efficiency, and create a safer driving experience.

The next stage of automation will focus on smart infrastructure, connected vehicle networks, and more advanced self-driving capabilities. As these innovations develop, they will reshape how people commute, how businesses handle deliveries, and how cities plan transportation systems. Companies that focus on automation now will be better positioned to lead the industry into the future.

Automation is transforming efficiency in the automotive industry by making processes faster, smarter, and more cost-effective. From AI-driven manufacturing and logistics to automated customer service and safety testing, every aspect of the industry is evolving. Businesses that invest in automation technology, predictive analytics, and AI-powered systems will have a competitive edge in a rapidly changing market. The automotive industry is driving the future of efficiency, innovation, and sustainability.