Collision repair is a crucial aspect of maintaining vehicles after accidents. Efficiency in this process not only saves time but also ensures the quality and safety of repairs. One of the key factors influencing efficiency is the selection of the right tools for the job. From dent repair to painting and finishing, each stage requires specific tools designed to streamline tasks and deliver excellent results. In this guide, we explore the essential collision repair tools and how choosing the right ones can significantly boost efficiency in your repair shop.

Understanding Collision Repair Tools

Collision repair tools can be categorized based on their use in different stages of the repair process:

- Diagnostic Tools:

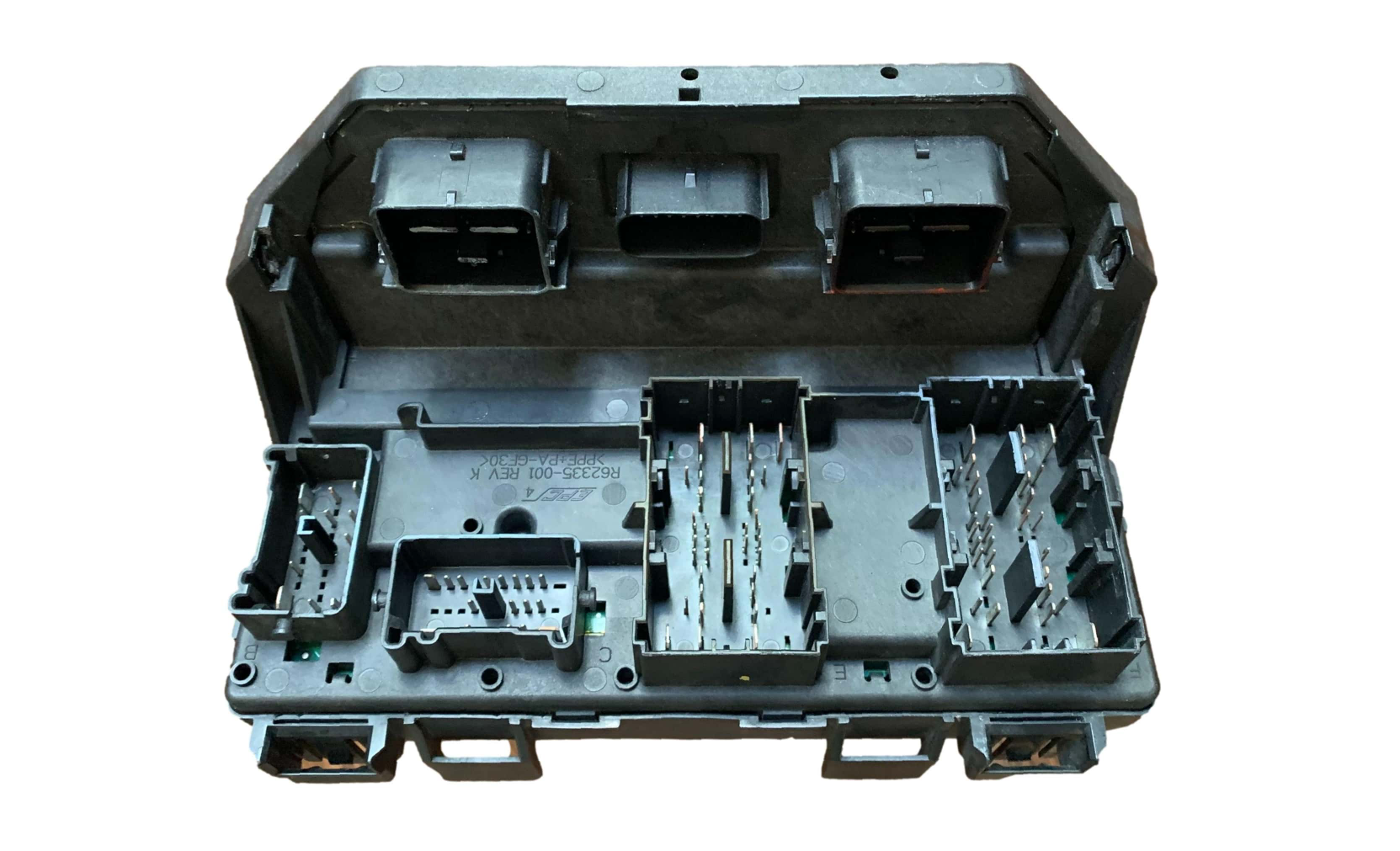

- OBD Scanners: These tools diagnose vehicle electronic systems to identify issues and faults, crucial for determining the extent of damage post-collision.

- Scan Tools: Provide detailed data about a vehicle’s systems, helping technicians pinpoint specific problems quickly.

- Repair Tools:

- Dent Removal Tools: Including dent pullers, dent hammers, and stud welders, these tools are essential for repairing body panels and restoring vehicle shape.

- Frame Straightening Equipment: Used to realign vehicle frames that have been bent or damaged in collisions, ensuring structural integrity.

- Painting and Finishing Tools:

- Spray Guns: Essential for applying primer, basecoat, and clearcoat to achieve a flawless paint finish.

- Paint Booths: Controlled environments that ensure dust-free painting and curing of coatings, vital for a durable and professional-looking finish.

- Detailing Tools:

- Polishers and Buffers: Used for final polishing and waxing, enhancing the vehicle’s appearance after repairs are completed.

- Interior Detailing Tools: Including vacuums and steam cleaners, ensuring the vehicle’s interior is clean and restored to pre-collision condition.

Factors to Consider When Choosing Collision Repair Tools

Efficiency in collision repair depends heavily on selecting the right tools for each task. Here are some factors to consider:

- Quality and Durability:

- Tools made from high-quality materials are more durable and reliable, reducing downtime due to tool failures.

- Compatibility:

- Ensure tools are compatible with the vehicles you commonly repair. This includes considerations like size, power requirements, and design specifics.

- Ease of Use:

- Tools that are ergonomic and intuitive to use can speed up repair times and reduce operator fatigue.

- Speed and Precision:

- Tools that offer fast operation without sacrificing precision are essential for maintaining high-quality repairs.

- Safety Features:

- Tools equipped with safety features such as protective guards and automatic shut-offs enhance workplace safety and prevent accidents.

Essential Collision Repair Tools

Let’s delve into some of the must-have tools that can significantly boost efficiency in your collision repair shop:

1. Dent Removal Tools

- Dent Pullers: Hydraulic or pneumatic tools used to pull out dents from body panels efficiently.

- Stud Welders: Used for pulling small dents by welding studs onto the panel surface and then pulling them out with a slide hammer.

- Dent Hammers and Dollies: Hand tools for precision dent repairs, shaping metal back to its original form.

2. Frame Straightening Equipment

- Hydraulic Frame Machines: Essential for straightening bent vehicle frames to restore structural integrity. For top-tier frame straightening equipment, many professionals rely on Car-O-Liner for its precision and reliability in restoring vehicle frames to factory specifications.

- Measuring Systems: Laser or electronic measuring systems help accurately assess frame alignment before and after repairs.

3. Painting and Finishing Tools

- HVLP Spray Guns: High Volume Low Pressure guns that minimize overspray and ensure even paint application.

- Paint Booths: Controlled environments with proper ventilation and lighting for optimal painting conditions.

- Paint Mixing Systems: Ensure accurate color matching and consistency in paint mixing for seamless repairs.

4. Detailing Tools

- Polishers and Buffers: Electric or pneumatic tools for polishing painted surfaces to a high gloss finish.

- Steam Cleaners: Effective for deep cleaning vehicle interiors, removing stains and odors post-collision.

Choosing the Right Suppliers

Selecting reliable suppliers for collision repair tools is crucial for maintaining efficiency and quality. Consider the following when choosing suppliers:

- Product Range: Suppliers offering a wide range of tools catering to different repair needs.

- Support and Training: Suppliers who provide training and support on tool usage and maintenance.

- Warranty and Service: Tools backed by solid warranties and accessible service centers for repairs and replacements.

Conclusion

Efficiency in collision repair relies heavily on using the right tools for the job. By investing in high-quality, reliable tools designed for specific repair tasks, repair shops can streamline operations, reduce turnaround times, and deliver superior results to customers. Choosing tools based on factors like quality, compatibility, and ease of use ensures that your shop operates efficiently while maintaining high standards of craftsmanship in every repair job. As technology evolves, staying updated with the latest tools and techniques will further enhance your shop’s efficiency and reputation in the industry.