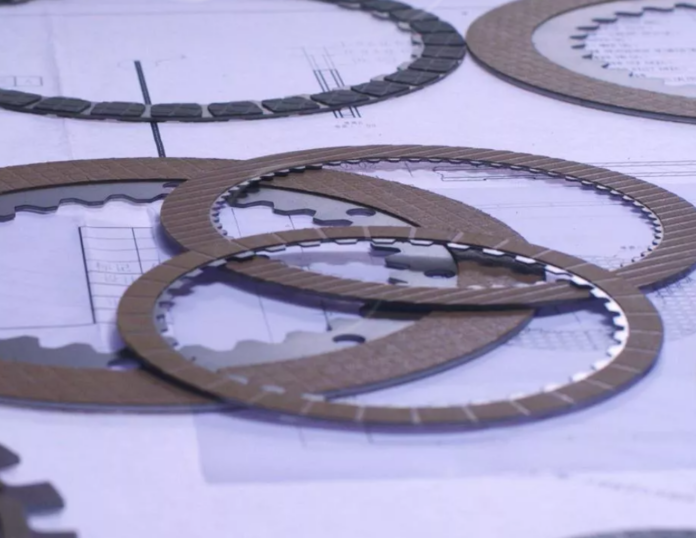

In modern automatic transmissions (AT), dual-clutch transmissions (DCT), and heavy-duty off-highway drivetrain systems, wet paper-based friction plates are far more than simple consumables. They are the most critical components for power engagement, engineered from a sophisticated composite of cellulose, synthetic fibers, heat-resistant resins, and friction modifiers. These components are designed to perform under the extreme hydraulic conditions of Automatic Transmission Fluid (ATF).

Why Paper-Based Materials Are Essential for Wet Environments

Paper-based friction plates do not just transmit torque; they function as a vital part of the hydraulic control system. Their microscopic structure directly dictates the vehicle’s drive quality:

- Exceptional Porosity: The sponge-like micro-pores in the friction material allow for the rapid expulsion and absorption of the oil film. This ensures a linear and seamless transition between “slipping” and “lock-up” phases during engagement.

- Anti-Shudder Performance: High-quality paper friction plates feature a specific negative friction-velocity gradient. This characteristic is essential for suppressing “shudder” during gear shifts, delivering the silk-smooth driving experience expected in premium vehicles.

The TCO Paradox: Why Cheap Friction Plates Cost More

When evaluating the value of transmission friction plates, one must look beyond the “unit price” and focus on the Total Cost of Ownership (TCO). Choosing low-quality, budget-grade components is often a case of “saving pennies but wasting thousands”.

1. The “Leverage Effect” of Labor Costs

Wet clutches are buried deep within the transmission core. Replacing a single set of friction discs requires a complete transmission removal (“drop”), full teardown, hydraulic circuit cleaning, and a total refill of expensive ATF.

- The Logic: The ratio of labor to parts cost often exceeds 5:1. Premium friction plates can extend the maintenance interval by more than 3 times, effectively saving the cost of two major overhauls and the associated downtime.

2. Operational Downtime and System Failure Risks

- Revenue Loss: For commercial fleets or heavy machinery, a single day of unexpected downtime can result in losses far exceeding the price difference between parts.

- Chain Reaction: Low-quality plates are prone to material delamination. Once friction debris enters the hydraulic system, it can destroy the Valve Body, escalating a simple plate replacement into a full transmission failure.

Failure Mode and Effects Analysis (FMEA): From Micro-Charring to System Collapse

Understanding the technical failure path of inferior paper-based plates is crucial for quality assurance:

1. Glazing: The Start of Performance Decay

When inferior materials face thermal loads beyond their limit, the fibers and resins undergo physical transformation, forming a hard, smooth “glazed” oxidation layer.

- The Consequence: The friction coefficient μ plummets, triggering a thermal runaway cycle: “Slipping → More Heat → More Slipping”. This damage is irreversible, and the transmission will not recover even after cooling.

2. Spalling and Delamination: The Systemic Poison

Under high temperatures and intense hydraulic shear stress, budget plates often lack the bonding strength to remain intact, causing the friction layer to peel off in flakes.

- The “Valve Body Killer”: These microscopic fibers circulate through the oil lines. Since modern solenoid valves operate with micron-level precision, this debris causes valve sticking, leading to Slam-shifts or total gear lock-up.

3. Thermo-Elastic Instability (TEI) and Steel Plate Scorching

Uneven heat distribution creates localized “hotspots” during friction engagement.

- Collateral Damage: Due to inconsistent material density, inferior plates cause localized overheating in the mating Steel Plates, leading to Coning (warping).

- The Result: Even when the clutch is disengaged, warped steel plates cause abnormal drag torque, leading to continuous overheating and the eventual melting of the entire Clutch Pack.

Value Comparison Summary

Performance Metric Premium/OE Paper Friction Plates Inferior/Budget Friction Plates

Microstructure Uniform porosity; superior oil film management Inconsistent; prone to localized hotspots

Chemical Stability Fully compatible with ATF additives May release harmful substances; accelerates oil oxidation

Thermal Threshold Rated for 350℃ and above Charring begins below 200℃

Failure Impact Predictable wear; protects valve bodies Spalling debris; contaminates entire hydraulic system

Conclusion

In a drivetrain system, a friction plate is not just a wear part; it is a precision fluid-dynamic controller. By investing in high-quality paper-based friction plates, you are purchasing “coefficient stability” and “hydraulic system cleanliness”. In the face of complex transmission engineering, selecting premium components is the most responsible choice for both safety and capital.