The world of automotive engineering is complex and fascinating, with each component playing a crucial role in the efficient functioning of a vehicle. Among these components, automotive pumps stand out as indispensable. But what often goes unnoticed is the significance of quality bearings in these pumps. Bearings are the unsung heroes that keep the machinery running smoothly, ensuring performance and longevity. This blog post dives into the role quality bearings play in automotive pumps and why they are critical for optimal vehicle performance.

The Science Behind Bearings

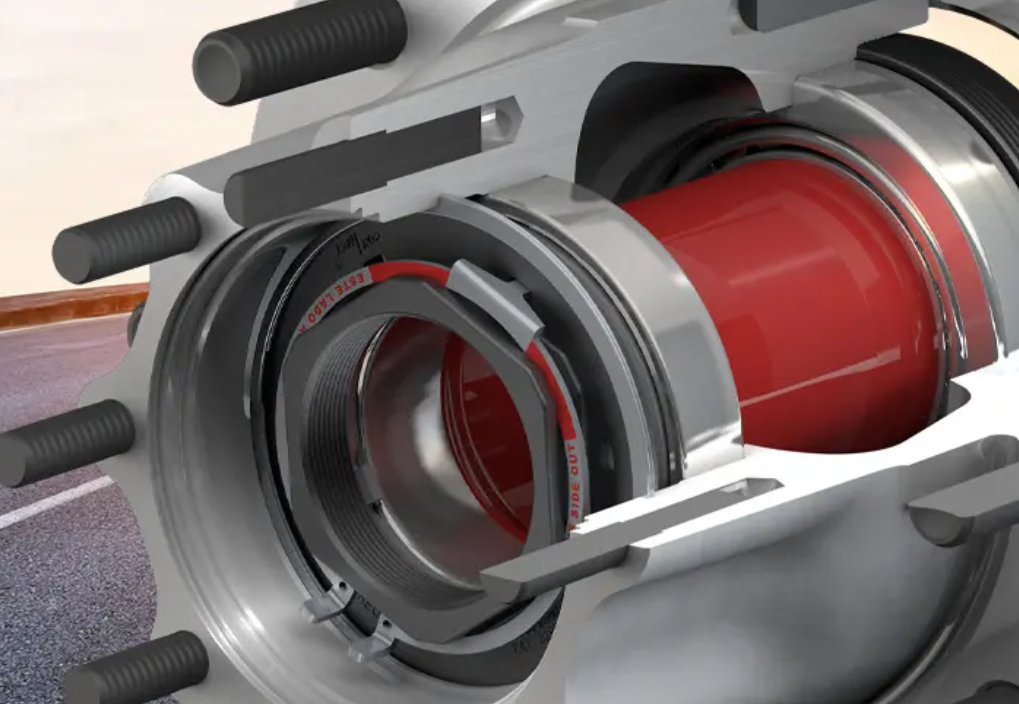

Bearings are not just simple metal rings; they are marvels of engineering designed to handle immense loads and extreme conditions. At their core, bearings consist of rolling elements, such as balls or rollers, placed between inner and outer rings. These elements reduce friction by rolling rather than sliding, which minimizes energy loss and wear. Bearings in automotive pumps must be made from materials that can withstand high pressures, temperatures, and corrosive fluids, often involving advanced metallurgy and precision manufacturing.

Why Bearings Matter in Automotive Pumps

Bearing is a critical component in automotive pumps, serving as the intermediary that allows the pump components to rotate with minimal friction. Imagine the pump as the heart of the vehicle, circulating fluids to keep the engine cool and lubricated. The bearings in the pump are analogous to valves in the human heart, ensuring the smooth and efficient flow of fluids. Without high-quality bearings, the pump wouldn’t function properly, leading to increased wear and tear, overheating, and potential engine failure.

Advancements in Bearing Technology

Driven by the need for increased efficiency and performance, innovation in bearing technology continues to evolve. Modern bearings now incorporate advanced materials like composites and ceramics, which offer reduced weight and superior strength. Additionally, innovations in coatings and lubrication systems are enhancing the durability and performance of bearings, making them more reliable and efficient. For those looking to extend the life of their pumps, it might be beneficial to consider options to replace your pump bearings as part of routine maintenance.

Types of Bearings Used in Automotive Pumps

Several types of bearings are used in automotive pumps, each suited to specific applications.

- Ball Bearings: These are the most common type, known for their ability to handle both radial and axial loads. They are ideal for water pumps.

- Roller Bearings: Roller bearings are designed to handle heavier loads and are often used in fuel pumps.

- Thrust Bearings: These are specialized to handle axial loads and are typically used in high-pressure applications such as oil pumps.

- Needle Bearings: These bearings have a high load-carrying capacity and are used in applications where space is limited.

The Impact of Quality on Performance

The quality of bearings directly impacts the performance and durability of automotive pumps. High-quality bearings reduce friction, which enhances the efficiency of the pump and minimizes heat generation. This leads to improved fuel efficiency and lower emissions, contributing to the vehicle’s overall performance. Moreover, high-quality bearings have better resistance to wear and corrosion, extending the pump’s lifespan and reducing maintenance costs.

The Importance of Regular Maintenance

Regular maintenance of automotive pumps and their bearings cannot be overstated. Even the highest quality bearings can suffer from wear and tear over time. Routine inspections can help identify potential issues before they escalate into serious problems. Replacing worn-out bearings promptly and ensuring they are well-lubricated can extend the life of the pump and the vehicle.

The Role of Lubrication

Lubrication is vital for the optimal functioning of bearings. It reduces friction and wear, but also helps in dissipating heat and protecting against corrosion. Quality bearings often come with advanced lubrication systems that ensure consistent performance even under extreme conditions. Depending on the application and operating environment, the type of lubricant used can vary.

Bearings in Electric Vehicles

The role of quality bearings is becoming even more critical as the automotive industry transitions toward electric vehicles(EVs). EVs often demand higher efficiency and lower maintenance and different performance requirements. Advanced bearings designed for EV applications help reduce energy loss and ensure the smooth operation of electric motors and other components.

Environmental Benefits

Using high-quality bearings in automotive pumps also has environmental benefits. By enhancing pump efficiency and reducing the need for frequent replacements, they contribute to lower resource consumption and waste. Improved fuel efficiency in traditional combustion vehicles also means reduced greenhouse gas emissions, making quality bearings an eco-friendly choice.

Quality bearings are undeniably critical in the seamless operation of automotive pumps. They are pivotal in ensuring efficiency, longevity, and overall performance. From the science behind their design to the materials and lubrication that keep them running, bearings deserve more recognition for their contribution to automotive engineering. Understanding the importance of quality bearings can lead to more informed vehicle maintenance and performance optimization decisions.