Many warehouses depend on practical upkeep habits that keep daily tasks moving without delays. Teams work faster when equipment stays reliable, and parts stay within reach. Clear routines help workers stay on track, reduce sudden breakdowns, and support a steady pace during busy periods. Many facilities now rely on simple digital resources and organized systems that help them track repairs and replacements. These tools also help staff understand what each machine needs and when.

Here’s how facility managers can optimize internal operations:

Create a Clear Maintenance Routine

A simple routine gives warehouse teams a steady path to follow. Daily checks help staff catch small issues early before they slow down the day. A short checklist works well for most teams, as it keeps tasks easy to remember. Workers can look over lifts, carts, and other tools before each shift begins. When everyone follows the same routine, the entire facility stays more organized. A consistent rhythm also helps supervisors understand what needs attention. Clear maintenance routines cut confusion because every team member knows what to look for. This approach supports better planning and fewer unexpected interruptions.

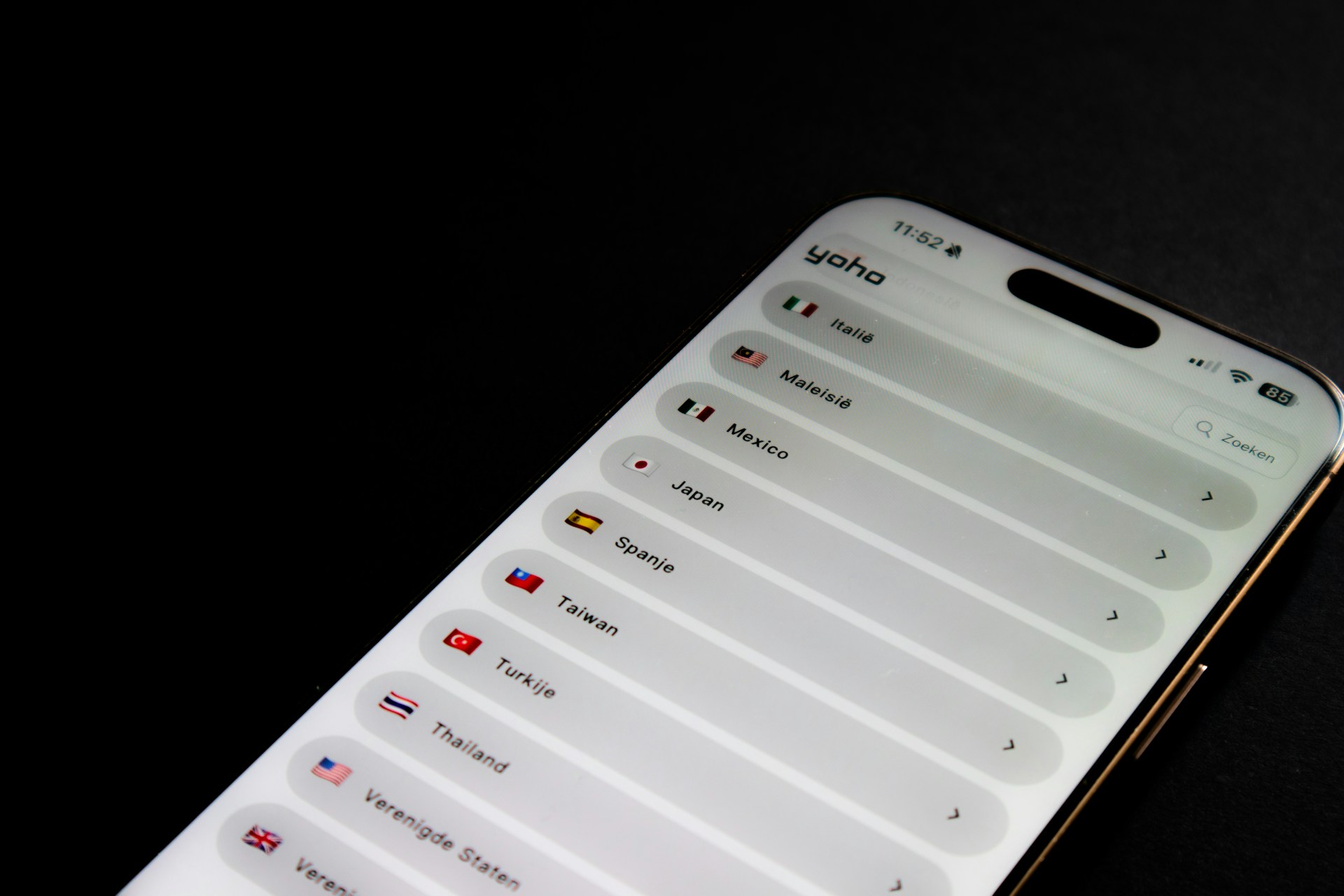

Use the Right Parts and Support Resources

Warehouses often benefit from having a reliable source for replacement parts. Many teams rely on suppliers that offer detailed product lists, quick ordering options, and parts that match a wide range of equipment. Reliable companies offer forklift components, search tools, clear product descriptions, and support for different machine models. This makes it easier for teams to pick what they need without guessing. These resources keep workers confident during repairs because they know they can find the right items fast. Access to a forklift parts catalog online helps reduce delays and supports steady workflow planning. With the right parts on hand, repairs stay quick and simple.

Keep Equipment Clean and Ready

Dust, dirt, and debris build up quickly in busy environments. When staff clean equipment each day, machines stay in better shape. A few minutes of wiping down surfaces, clearing vents, and checking wheels helps equipment run better. Cleaning also helps workers spot loose parts or signs of wear. This prevents bigger issues later. A clean work area supports better focus because staff can move without obstacles in the way. Sticking to a simple cleaning routine also lowers the chance of breakdowns. Teams can set short cleaning sessions during shift changes or at the end of each day. These small steps help equipment stay dependable.

Train Staff to Spot Early Equipment Issues

Good training helps workers recognize early warning signs in the equipment they use every day. When staff understand what normal function looks like, they can identify changes right away. Sounds, vibrations, and reduced performance often point to small problems. Teaching staff to report issues right when they notice them allows repairs to happen faster. This keeps machines ready for the next task. Hands-on lessons work best because workers learn directly from real equipment. Regular practice builds confidence and helps them respond quickly. The more familiar workers are with their tools, the better they protect the warehouse from slowdowns.

Track Wear and Tear on High-Use Machines

Some machines work harder than others, so they need close attention. Lifts, conveyors, and pallet tools handle heavier tasks each day. Tracking wear helps teams plan for repairs before problems appear. Staff can check for worn edges, tired wheels, or loose fittings. A simple logbook helps record these details. This makes it easier to understand how each machine ages over time. When teams keep track of wear patterns, they plan better and avoid downtime. A steady record also helps supervisors make smart decisions when parts need replacing. This habit supports a reliable flow throughout the facility because workers stay aware of each machine’s condition.

Organize Storage for Tools and Spare Parts

Good organization helps workers stay efficient. When tools and parts stay in the right place, repairs move faster. Clear labels, shelves, and bins help workers find what they need without searching. Many teams use color markers or printed tags to separate categories. This helps new staff learn the system quickly. An organized storage area also helps supervisors track supply levels. When parts start running low, staff can restock before delays happen. Keeping the area neat also improves safety because clutter causes accidents. A well-arranged storage space supports quick repairs, steady workflow, and fewer interruptions during busy periods.

Use Digital Tools to Log Maintenance Work

Digital logs help teams track upkeep tasks without confusion. Workers can enter notes after each repair, list completed checks, and update records in real time. These tools allow supervisors to see which machines received attention and what still needs work. Some systems send reminders when parts need inspection. This keeps everyone aware of upcoming tasks. Digital logs also help new staff understand past problems and how they were fixed. These records create consistency across shifts. When teams rely on clear digital systems, work becomes easier to coordinate. The entire facility benefits from organized tracking and better communication.

Review Equipment Performance Often

Regular check-ins help teams understand how well machines function each week. When supervisors review performance, they notice patterns such as slowing speed or repeated issues. Short meetings help teams share feedback from daily tasks. These discussions help staff decide whether a machine needs a quick repair or a full replacement. Keeping track of performance trends guides smart planning. Workers also feel more involved when they can share what they observe. This builds awareness across the facility because everyone pays closer attention to the tools they use. Frequent reviews reduce surprises and help maintain stability in daily tasks.

Strong maintenance habits keep warehouse workflows steady and predictable. When teams clean equipment, track wear, organize tools, train often, and use helpful resources, work stays on pace. Easy access to the right parts supports quick repairs, while digital logs simplify planning across shifts. A safety-focused approach and early preparation for busy seasons also help teams avoid delays. Each small step contributes to a reliable environment where workers feel confident and ready for their tasks. Practical upkeep routines support consistent performance and fewer disruptions, allowing daily tasks to move with better rhythm and focus.