Air quality and management are crucial for many businesses. Clean air benefits workers and ensures that machinery operates more efficiently and your business meets regulatory requirements. The air management system used can vary depending on the type of business. This article aims to analyze both the Web Scrubber and Baghouse systems and explore potential alternatives to aid business decisions.

Baghouse & Wet Scrubber Overview

Baghouses

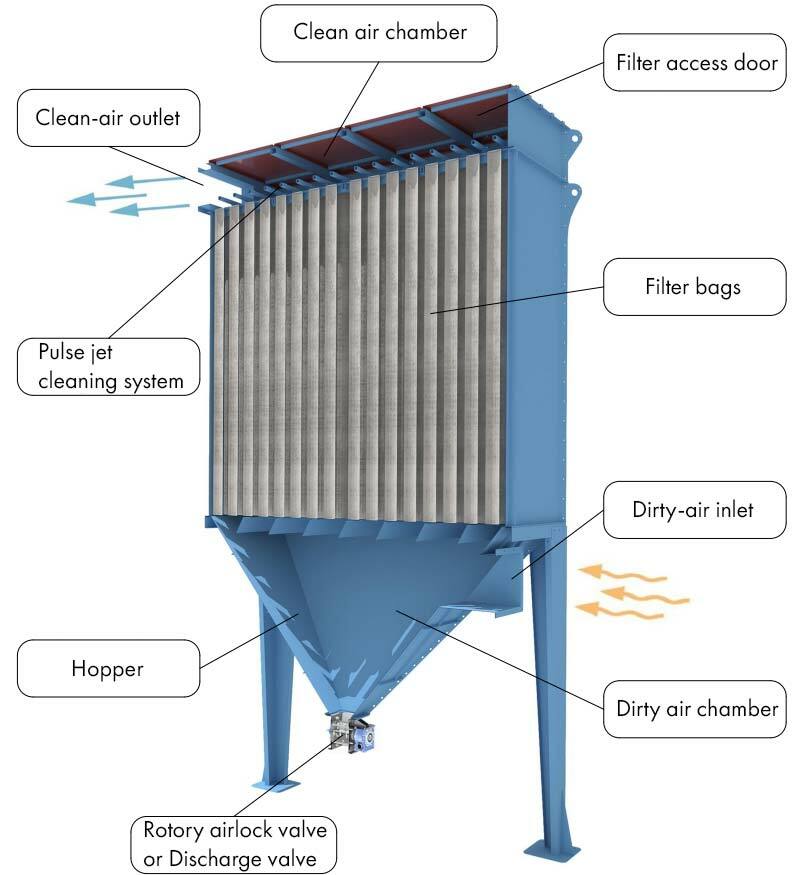

A commonly asked question regarding baghouses is: “what do baghouse filters remove”? The answer is primarily particulate matter, including dust, soot, and fine particles like metal. If you are a part of a business in lumber work, metallurgy, chemicals, textiles, and food, consider a baghouse solution for air management.

How does a baghouse remove contaminants? Fabric filter bags collect particles. Dirty air is fed in through the bottom of the baghouse control system. It then flows upward through the bags, allowing air to pass through the fabric while the particulates are left behind. The clean air is expunged out and fed to the business’ ventilation system.

Due to the nature of capturing the fine materials, baghouses must be regularly cleaned. Typical baghouses offer cleaning methods, including:

- Pulse Jet – A high-powered jet of compressed air inflates the air baghouse bags on the inside. This causes any caked-on dust to break off and fall into the hopper below for easy removal.

- Mechanical Shaking – A deceivingly complex solution. It involves shaking the interior bags with a built-in system to remove dust deposits. This can be abrasive to the machine, requiring more maintenance than a Pulse Jet system.

- Reverse Air – Similar to pulse jet, but with less power. This method is typically used in conjunction with other cleaning methods to be considered effective.

Wet Scrubbers

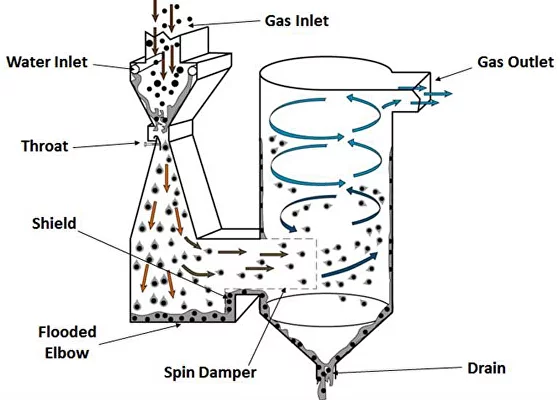

Wet Scrubbers use liquid to capture and remove pollutants such as gases, vapors, and airborne particulates. A wet scrubber is considered a good investment if your business specializes in chemical manufacturing, metal processing, power generation, or pharmaceuticals.

A wet scrubber removes contaminants by mixing the pollutants with a scrubbing liquid. Gas or air is drawn into the machine through an inlet. A water stream flows at the inlet with the gas, mixing as it goes through. The gas is then forced into a pool of the scrubbing liquid and filtered out through an outlet drain. The remaining pollution-free gas then exits through the gas outlet, reentering the air system as clean air.

Cleaning a wet scrubber will require more maintenance than a baghouse. Depending on the severity, this could result in disassembly while the maintenance is done.

Pros & Cons

Advantages to Baghouses

- High Efficiency – Baghouses operating at peak performance can filter out greater than 99% of particulate matter.

- Low Operating Costs – Baghouses require less maintenance and less cleaning compared to wet scrubbers.

- Flexibility – Baghouses can be added or removed more effectively than wet scrubbers and can handle varying dust challenges.

- Space Conscious – Baghouses are much smaller than other air filtration systems, allowing easy installation in limited spaces.

Disadvantages to Baghouses

- Particulate Limited – Baghouses are not effective at trapping gases or vapors.

- Clogging – If not properly maintained, they can easily clog.

Advantages of Wet scrubbers

- Versatile – Wet scrubbers are good at catching nearly all types of pollutants. Including gases, vapors, and particulate matter.

- High Efficiency – Akin to baghouses, wet scrubbers achieve greater than 99% effectiveness on contaminants.

- Chemical Effectiveness – Wet scrubbers are particularly good at removing pollutants in chemicals.

Disadvantages of Wet scrubbers

- High Operational Cost – Requires more maintenance and the cost of the scrubbing liquids.

- Wastewater Removal – Wastewater must be disposed of, which can cost significantly.

- Space Unconscious – Wet scrubbers are much larger than baghouses, requiring additional piping to intake and outtake liquids.

Conclusion

When picking an air control system, a business must consider its needs carefully. Air filtration needs can vary depending on the type of pollutant produced. Not only will the company need to understand which systems work best for the pollutant, but they will also need to utilize space appropriately and ensure their selected system can function. Regardless, if you’re part of a business looking to install or replace an air system, use the above to help analyze some potential technologies that will ensure effective business performance.